Food

- Aromas, Cereals, Extracts, Coffee (black, green, mate tea)

- Hydrolysates of proteins

- Vegetable powder (carrot, beet, spinach, artichoke, bean and others)

- Fruits powder with load

- Corn and cassava derived, starch and maltodextrin

- Soy derived, soy milk, soluble extract, isolated soy protein

- Milk and milk derived

- Beer yeasts, cane, etc

- Fat powder

- Natural colorants (achiote paste - Bixin, grape anthocyanins)

- Synthetic colorants

- Marines derived

- Egg powder, egg, yolk and egg white (anchor all egg powder explanatory)

OBTAINING EGG, YOLK, EGG WHITE, ADDITIVATED EGG WHITE POWDER

Our equipment is suitable for water evaporation, so the appropriated model specification happens according to this parameter. Verify in: Technical Specifications of Spray Dryers Plants (link) the model that fits your project best, taking into account the amount of evaporated water according to the entrance and exit temperature adequated to the product that will be dried.

Exemple:

Product: Egg with 23% of solids. Water: 77% TE = 220°C and TS = 90°C

Equipment: DR-15.

Water Evaporation of 74 l/h.

The production will be around 23 kg/h of egg powder.

Accessory equipment for egg powder production:

- A washing egg equipment.

- A machine to break eggs.

- A peel transporter.

- A set of equipment to be used as a deposit, homogenization, "desglucosamento", etc.

- A pasteurizer.

- An atomization dryer (Spray Dryer) SPRAY PROCESS.

- The space requested for that equipment is approximately 140 m².

Advantages of the egg powder production:

- Practically 100% of the production will be used.

- Besides the eggs considered normal for commercialization, those without commercial value will be also used, in other words, the small ones, the ones in the beginning of the posture and the ones that will come to happen during the normal period of the posture, as well as the broken ones, etc.

- They can be produced all year long, even when the egg market "in natura" is not appropriated.

- The egg or the yolk and the egg white separately can be produced with the corresponding price advantages.

- Egg powder can be stored for six months or more, simply in fresh and dark place.

- Ten times more egg powder can be stored in the same space of a natural egg.

Observation:

- The indirect oven is indicated so that the combustion gases don't get in touch with the product, condition practically obligatory when it is an export product.

- The auxiliary atomizer continues working when there is the need for maintenance.

- Gas washer: where the legislation doesn't allow any pollution, the washer keeps the fine solids that would eventually pass through the chimney, only releasing water steams and combustion gases.

- Organic salts

- Inorganic salts

- Medicament in general

- Vaccines

- Medicinal plants extracts

- Nutraceutical plants extracts, etc

- Organic salts

- Inorganic salts

- Detergents in general

- Plastic

- Resins

- Catalysts and Coloring

- Fertilizing

- Defensive in general

- Natural and synthetic tannins, etc

- Ceramic products

- Kaolin

- Ceramic pigments

- Products for Feed & Food

- Organic fertilizers

- Concentration of organic residues

- Slaughterhouse by-products:

PRODUCTS TO BE DRIED IN SPRAY DRYERS EQUIPMENT BOVINE, SWINE, BOVID, OVINE, POULTRY AND FISH SLAUGHTER. (BY-PRODUCTS)

1. Total amino acids powder.

2. Liver powder.

3. Liver powder extract.

4. Liver powder peptone

5. Remains of meat powder peptone.

6. Bile powder (taurocholic).

7. Blood powder.

8. Hemoglobin and plasma powder.

1. TOTAL AMINO ACIDS POWDER.

Constituted by previously mixtures calculated of:

Heart.

Lung.

Stomach (Craw).

Spleen.

Liver.

Bowels.

Amygdala, etc.

Those by-products minced and passed in colloid mills are dried directly by the Spray Dryer Equipment. All those by-products can also be hydrolyzed and equally dried.

They contain all the well-known amino acids and other properties in a balanced form.

2. LIVER POWDER.

The fresh livers are minced, passed through a colloid mill and then transformed into powder by the Spray Dryer Equipment.

3. LIVER POWDER EXTRACT.

The minced liver is mixed with water and taken to isoelectric point (pH 5 up to 6). After that the mixture is boiled until the albumin starts (approximately 80 0 C).

After 30 minutes it is filtered and then concentrated up to approximately 30% through an evaporator (a vacuous) to obtain the appropriate concentration and to be processed by the Spray Dryer Equipment.

4. LIVER POWDER PEPTONE.

The liver is chopped and then put in a double bottom tank, made of stainless steel, with the necessary amount of water. After that the hidrolis is done with acids or enzymes and a temperature not above 40 0C or 45 0C. Once the digestion is finished, the temperature rises and defuses the enzymes, the filtering starts through a filter-press or a centrifugal sifter. After the final concentration through the Spray Dryer Equipment the powder is obtained.

5. REMAINS OF MEAT POWDER PEPTONE.

The meat remains should be digested in a double bottom tank for 12 or 14 hours and revolved through a slow agitator, the temperature should be 40 0C to 45 0C. The meat should be fat, tallow and tendons free, being previously minced. The digestion is done with hydrochloric acid and pure pepsin and later it is neutralized with sodic carbonate. It is filtered, and after being concentrated it passes through the Spray Dryer Equipment. The Pancreas can also be used, heating the product up to no more than 54 0C for 6 hours, shaking it uninterruptedly. The solution is filtered and evaporated up to no more than 60 0C a vacuous until obtaining the necessary concentration to pass through the Spray Dryer Equipment.

The weaker and harder the used meat is, the larger the income is - (13% to 14%).

The soft meat income doesn't overcome 10% of peptone.

Quanto mais fraca e dura, a carne utilizada, maior o rendimento �?(13% a 14%).

O rendimento de carne mole não supera 10% de peptona.

6. BILE POWDER (taurocholic).

The removed animal bile can be processed in the slaughterhouse directly in the Spray Dryer equipment, or it can undergo a previous treatment that consists of treating the fresh bile with the same amount of alcohol resting for 12 hours; it has to be filtered and heated up to eliminate the alcohol; concentrate it (no more than 25% of solids) and then pass it through the Spray Dryer Equipment.

7. BLOOD POWDER.

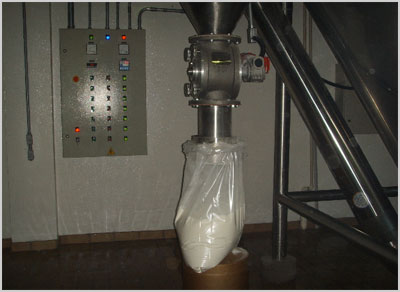

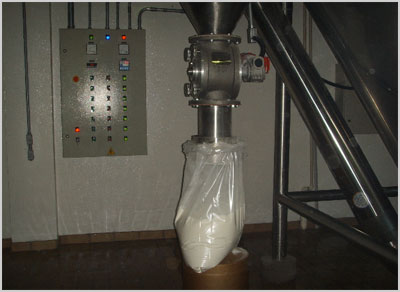

The Spray Dryer equipment used is standard and it is envased directly in 15 kg sacks of polyethylene and paper, in the exit of the hurricane. In the case of sanitary demands, a packing room can be built, connected to the deposit by a window, with a sloping chute where the product can slide and be packed. The work is the same for bovine, swine, bovide, ovine, poultry (chickens, ducks, turkeys, etc.) blood.

The income in profitable liquid blood is approximately 3% of the animal weight, in other words, a 450 kg bovine goes a long way from 12 to 16 liters per animal. The blood contains 18% of solids. That separate blood gives 60% of Plasma with 8% of solids, and 40% of Hemoglobin with 33% of solids.

For each animal, on average of 450 kg we will have:

| Blood | 2,5 kg powder |

| Plasma | 0,7 kg powder |

| Hemoglobin | 1,8 kg powder |

The drying temperatures used are:

| Blood and/ or Hemoglobin TE: | 350°C and TS: 90°C |

| Plasma TE: | 220°C and TS: 80°C |

8. HEMOGLOBIN ANS PLASMA POWDER

| Product | % Proteins % Ashes | % Humidity |

| Blood | 80 a 83 | 2 a 3 4 a 8 |

| Plasma | 90 a 92 | 2 4 a 6 |

| Hemoglobin | 70 a 75 | 3 a 4 4 a 7 |

For data consumption and equipment sizes, consult Spray Dryer Plants technical specifications

Portuguese

Portuguese Inglês

Inglês Espanhol

Espanhol